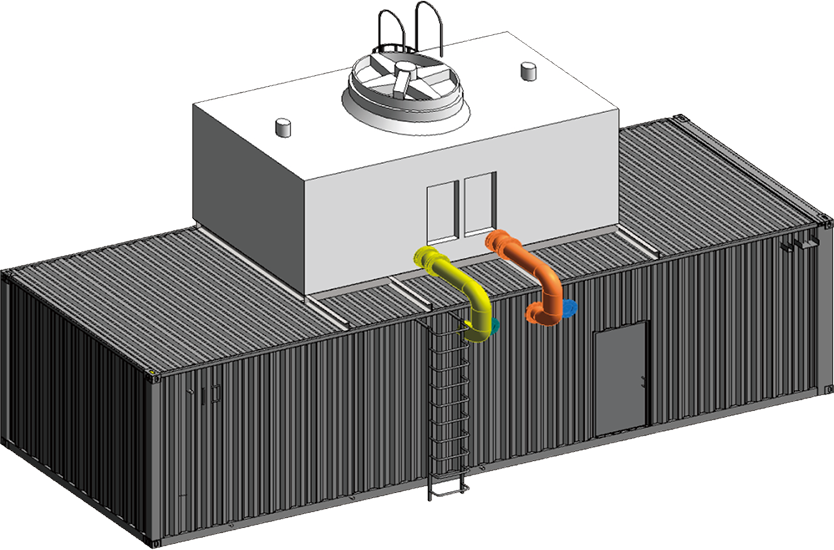

Overview

Solving the drawbacks of existing chillers

• The existing large chiller testing devices are basically made by professional companies, with complex systems and high cost. It occupies a large area.

• The experimental platform uses the cooling water to heat the chilled water, thus solving the problem of insufficient cooling load of the chilled water at the end of the test, and also reducing the cooling load of the cooling tower accordingly.

Fully simulates air conditioning test conditions

• The COP can be easily implemented to test the refrigeration mainframe at partial load.

• When the load of air conditioning cooling in the plant or office where the test system is located is lower than the cooling capacity of the main unit, the full load of the chiller can be reached through the bypass system of this device.

Used to cool factory or office space for air conditioning

• This test device can also be used in the summer for plant and office air-conditioning cooling.

Home

Home Products

Products Telephone

Telephone Messages

Messages